Innova RTR-02 Resistance Transducer

SKU Innova-RTR-02

₹4,000

Price includes GST (18%) ₹610.17

Input Range

Enter your text

Output 1

Please choose

Output 2

Please choose

Aux Supply

Please choose

In stock

1

Save this product for later

Innova RTR-02 Resistance Transducer

Product Details

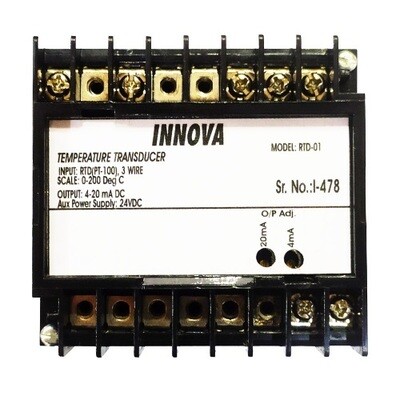

Brand: Innova

MPN: RTR-02

Innova RTR-02 Resistance Transducer — Industrial Resistive Transducer

The Innova RTR-02 Resistance Transducer converts resistance variation into a precise proportional electrical output. Ideal for industrial automation, panel mounting, PLC integration and laboratory measurement, the RTR-02 offers high linearity, temperature stability and rugged construction for continuous industrial service.

- High accuracy: ±0.5% FS (typical)

- Input: Resistance-based sensors (LVDT, Potentiometer, custom resistive sensors)

- Output: 0–20 mA or 4–20 mA or 0–5 V or 0–10 V - Dual (Factory Set)

- Mounting: Panel / DIN-rail compatible

- Protection: IP20 / industrial-grade enclosure

Technical Specifications

Technical Specifications

| Model | RTR-02 |

|---|---|

| Input Type | Resistance-based sensors (LVDT, Potentiometer, custom resistive sensors) |

| Output | 0–20 mA or 4–20 mA or 0–5 V or 0–10 V - Dual (Factory Set) |

| Accuracy | ±0.5% FS (typical) |

| Operating Temp. | -20°C to 70°C |

| Supply Voltage | 90-270V AC/DC or 10-30V DC |

| Response Time | <200 ms |

| Mounting | Panel / DIN rail |

| IP Rating | IP20 |

| Warranty | 12 months |

Why choose Innova RTR-02?

- Reliable readings — Low drift and temperature compensation for long-term stability.

- Easy integration — Standard 4–20 mA / 0–10 V outputs for PLCs and data loggers.

- Rugged design — Designed for industrial panels and continuous operation.

- Cost-effective — Competitive pricing for bulk panel installations.

Frequently Asked Questions

Frequently Asked Questions

What applications suit a resistance transducer?

Industrial process control, temperature measurement with RTDs, load cell/resistive bridge signals, laboratory instrumentation and any application that needs resistance-to-current/voltage conversion.

How is the RTR-02 calibrated?

The RTR-02 is factory-calibrated. Field calibration instructions and step-by-step procedures are available in the downloadable datasheet (see the datasheet link above).

Can I use RTR-02 with PLCs?

Yes — standard 4–20 mA and 0–10 V outputs make RTR-02 compatible with most PLCs and SCADA systems. Ensure the PLC input expects the same signal type and span as the transducer output.

Customer reviews

Reviews only from verified customers

No reviews yet. You can buy this product and be the first to leave a review.

You May Also Like

BEST SELLER

Innova CAL45-AV 4.5 Digit mA & mV Source

Innova CAL45-AV 4.5 Digit mA & mV Source

Save 39%

₹7,500

Display prices in:INR